Meet Our Trusted South Florida Roofers

E.W. MacDowell Inc. Roofing has offered the absolute best quality roofing services in South FL since 2000. Whether you need us to find the problem and assess the damage, fix a roof leak, or replace your roof entirely, we are established South Florida roofers.

All roof leak repairs come with a warranty that lasts the lifetime of your roof. This is a testament of how much we believe in the quality of our work.

Who We Are

Play Video about MacDowell Roofing Contractor South FL

A Top South Florida Roofing Company

Welcome to E.W. MacDowell Inc, one of the highest rated roofing companies in South Florida. As a leading provider of roofing services, we are dedicated to helping homeowners in South Florida protect their homes from the harsh Florida weather with high-quality roofing materials as well as a cohesive team of experienced contractors.

As a homeowner or business owner, you can count on E.W. MacDowell Inc. to deliver the highest quality services to you and your roof. Whether it’s a durable tile roof, a classic shingle roof, or a modern metal roof, our team is equipped to provide unmatched service. We understand that each homeowner and business owner has unique needs, and our expertise in various roofing materials ensures that every roof we work on is not just functional but also aesthetically pleasing. Trust us to transform your roofing vision into reality.

Roof Repair

Our qualified and experienced roofing contractors can handle any repair job, from minor leaks to major structural damage.

Roof Inspections

Our qualified roof experts will come to assess your roof and give you a complete, honest report so you know what to expect.

Roof Replacements

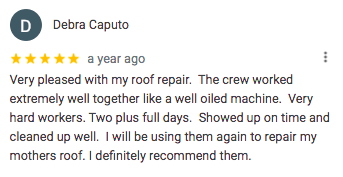

Sometimes quick fixes just aren’t enough; when you need a roof replacement, we have your back. See our reviews. Our roof replacement services are the best to be found.

Need to find the source of a leak? Stop a roof from sagging? Replace your tile shingles with metal? We have the right solutions to fit your needs.

Why Choose E.W. MacDowell Inc?

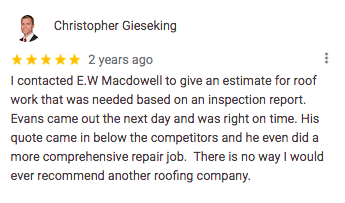

When you need to fix a roof leak or a sagging roof, you might panic. If you search for “roof repair near me” or “affordable roof repair,” you will find many roofing companies to choose from. So why choose us? E.W. MacDowell Inc is one of the highest rated local roofing contractors in South Florida, and when you are considering a roofer, our company should be the first one you call. We are experienced, friendly, and professional, and we love having the chance to show you just how devoted to excellence we are. Look at the rest, but come back to the best; we are sure that we can prove to you how well-earned our stellar reputation is after just one visit. E.W. Macdowell Inc. truly is a reliable and experienced South Florida roofing company, (just read our many reviews!) and we are just one phone call away.

E.W. MacDowell Inc.

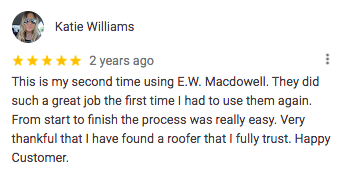

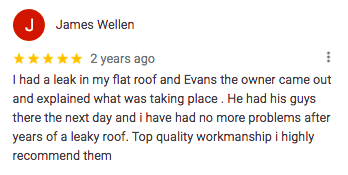

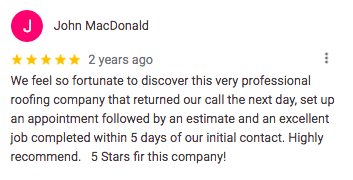

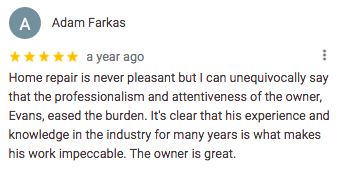

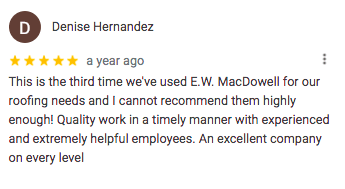

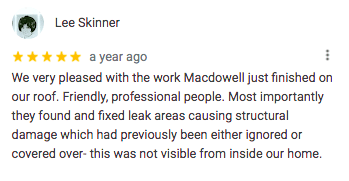

A 5 Star Roofing Service Company

For Quality Roofs Services

With dozens of 5 star reviews collected over the years, we have a well-deserved reputation for being fair, showing integrity in our dealings, having an amazing work ethic, and being the best roofing contractor in South Florida.

We take care of all kinds of roof repairs, whether you need minor roof repair, emergency roof repair, or an inspection or maintenance of any kind. There is no substitute for the experience we have gained over our 20+ years of serving South FL.

E.W. MacDowell Inc. will work with you to solve your roofing needs and offer our expertise at every turn. So, if there is anything your roof needs, don’t hesitate. Call us today; we promise you’ll be happy that you did.

If you don’t think that you can afford the cost of fixing a roof leak, think again. We ensure that we complete the job thoroughly the first time around for a price that won’t break the bank. Nobody has the same attention to detail and passion for Florida roofing that we do. This fact shows in every aspect of our work, from the way that we greet you when we pick up the phone, to the way that we shake your hand and thank you for your business as we celebrate a job well done.

South Florida Roofing Service: What sets us apart?

Whether you’re in need of a new roofing system installation, urgent roof repair, or regular maintenance, our team of great contractors at E.W. MacDowell INC is here to provide top-tier services. With a blend of vast expertise and advanced skills, our experienced roofers handle all your roofing needs across the county. We’re committed to using only the finest materials and techniques, ensuring your roof is not just durable, but reliable and long-lasting.

As a 5-star rated roofing business in South Florida, E.W. MacDowell INC takes pride in our well-earned reputation for excellence. Over the years, our contractors have consistently delivered exceptional results, earning us glowing reviews and a loyal customer base. If you’re searching for the best roofing company in South Florida, you’ve found us. Contact us today for a consultation, and let us demonstrate why we are the go-to contractors for all your roofing needs.

No matter the size of the job, your best choice is E.W. MacDowell INC, the top roofing contractor in South Florida. You can relax knowing your roofing requirements are in the hands of the best in the business. When you need it done swiftly, correctly, and at a reasonable price, there may be alternatives, but none can rival our quality and meticulous attention to detail. Trust our contractors to deliver unparalleled roofing services, setting a high standard in the industry.

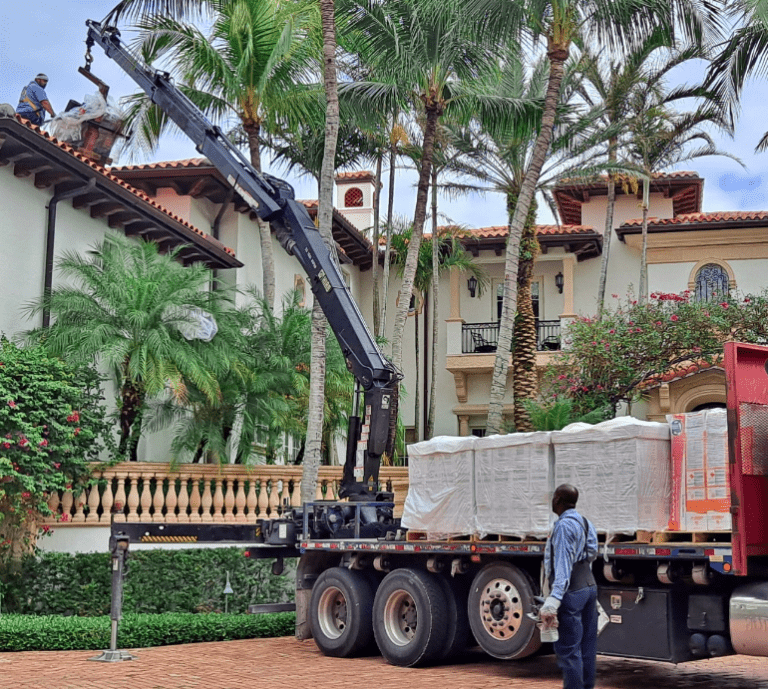

Recent South FL Roofing Company Projects

Commercial Roof Replacement in South Florida

Residential Roof Replacement in South Florida

Commercial Roof Replacement

Homeowners aren’t the only ones who need South Florida roof repair and replacement services. Commercial buildings need structurally sound, fully functional roofs to keep employees, inventory, and customers from being exposed to the elements and all the problems that come with them. If you notice any damage to the roof of your South Florida commercial building, don’t hesitate to call the experts at E.W. MacDowell INC. E.W. MacDowell offers all manner of commercial roof repair; South Florida flat roofs, metal roofs, and even tile can be fixed or replaced in no time with our roofing company. We ensure the work area remains clean and safe for your customers. Florida business owners have been trusting the E.W. MacDowell company with their south Florida roofing needs for decades.

FAQs

The cheapest option is to get your roof maintained regularly to minimize the need for repairs at all, but no matter how diligent you are, every roof is eventually going to need to be fixed. When that happens, you might be wondering to yourself how much it is going to cost. It’s impossible to quote a job accurately but repairs can range from a few hundred to a few thousand based on the roofing materials required and area of roof that must be fixed.

Just use the search engine of choice to look up “best local roof repair companies near me” In fact, you have already found the best roofing company South Florida has to offer, and we are so glad that you are here. We believe that E.W. MacDowell Roofing is, hands down, the best roofing company in South Florida, and our customers do, too. Take some time to read some of our reviews, and when you are ready to be blown away by the top name in roof repair in South Florida, click or call; we’re at your service.

Always opt for locals when you’re looking for roofers, South Florida. Florida locals like us know the exact requirements needed to withstand the gale-force winds and torrential rain that come with hurricane season. South Florida roofing contractors should be able to tell you the benefits of common roofing materials, and the best roofing companies in South Florida know that full replacements are sometimes required.

The most popular roofing materials in South Florida are tile, metal, and asphalt (slate). Roofing in South Florida means taking extreme weather, high humidity, and sweltering heat into account when selecting the materials that work best for your home.

Referrals Are Our #1 Source of Business

Having been a business owner in the construction industry for over 40 years, I have worked with a lot of contractors. I recently had the pleasure of meeting and working with Evans MacDowell, owner of E.W. MacDowell, Inc. Through every step of the way, I found Evans, his staff and crew to be exceptional. They were responsive and on time, courteous, knowledgeable, and thorough in the completion of top-quality work on my roof. I wholeheartedly and highly recommend Evans/E.W. MacDowell, Inc. for both new construction and roof repairs – very satisfied!

Ambassador Ned L. Siegel

Our roof was first installed by EW before we even purchased our house. We recently had them come out to fix some cracked tiles and they were extremely responsive and efficient in completing the job. We were provided photos of all the repairs which will be helpful for insurance purposes. Highly recommend!

Alana McHugh

E.W. Macdowell Inc. did an absolutely MAGNIFICENT job on our roof. The owner, Evans and his staff were top notch. We just had our final inspection and the inspector said that they did a beautiful job! Can't get any better than that!!!

Patty Kapplan